- Info

ltm-1000

Laser Thermal Microinjector LTM-1000

|

|

| The world’s first micro-injector capable of injecting picoliters directly

into a rigid plant cell wall. |

|

| Features |

|

|

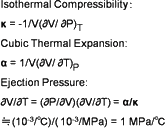

Capable of producing high ejection pressures (+/- 1MPa per 1°C) |

|

Target Individual Cell Components |

|

Dramatically reduces Cell Death |

|

Multiple injections without clogging. |

|

Quick Set-Up & Operation |

|

| The product supported by: The project to develop "innovative seeds"

of Japan Science and Technology Agency (JST) |

|

| Application |

|

Microinject Materials: DNA, RNA, Protein, etc |

|

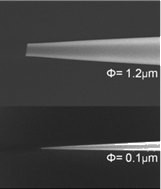

Capillary Tip Sizes: 0.1-0.5µm Ø |

|

Cell Types: Plant, Fungi, Mammalian, Organelles |

|

|

Stereoscope Microinjection Set-Up Using LTM-1000

| Laser Emission Wavelength |

980nm |

| Laser Drive System |

ACC, Max. 2.5A, Continuously-Variable |

| Temperature Control |

Peltier system 25.0°C-40.0°C (0.1°C increments) Continuously-Variable |

| Optical Output |

1.3W |

| Dimensions |

170W x 325D x 120H mm |

| Weight |

4.1kg (includes laser head) |

| Power |

100V- 240V, 50/60Hz |

|

|

|

Number of injection into Plant Cells with a single capillary |

|

|

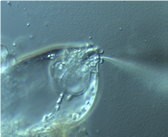

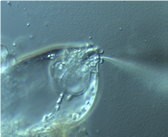

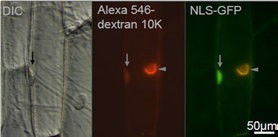

Injection into the female gametophyte of plant |

|

|

|

|

|

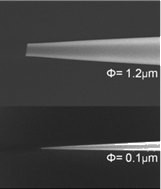

| Conventional Method(A) LTM-1000(B) |

Size Difference in Capillary Tips |

Damage cell using conventional method pictured on Left(A),

No damage using LTM-1000 pictured on Right(B). |

|

|

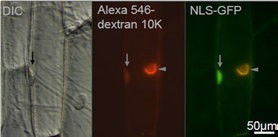

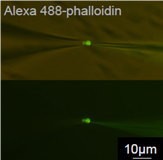

Injection of siRNA into the naked female gametophyte of Torenia. |

|

|

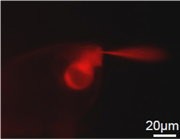

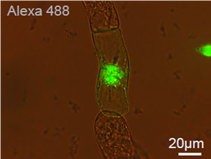

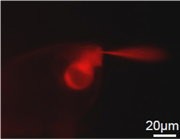

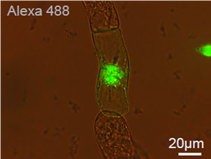

Injection of plasmids into a nucleus of onion epidermal cells |

|

|

|

|

|

|

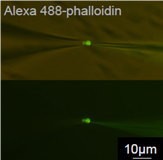

Injection of antibody into plant cells |

|

|

Injection into Budding Yeasts |

|

|

Injection into Chloroplasts of Cyanidioschyzon merolae |

|

|

|

|

Above information provided by: Dr. Tetsuya Higashiyama, Division of Biological Science, Graduate School of Science, Nagoya University |

“Laser-assisted Thermal-expansion Microinjection”

Patent Application Number (2004) 361448 |

|

|

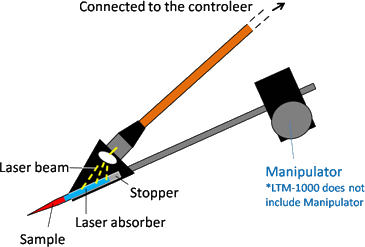

Heat-induced expansion of liquid in a sealed capillary generates high pressure, which enables injection by capillaries with the tip diameter around 0.1µm (Knoblauch et al., Nature Biotech., 1999).

As the heat source, we chose laser beam which enabled us to directly heat hydrophobic liquid containing laser absorber through the capillary glass and to precisely control the injection flow. |